Overhead line

Important elements of our network are the overhead lines and the 20,000 or so pylons that carry the conductor cables. These are usually positioned 300 to 500 metres apart. The pylons are for the most part built as steel lattice masts – a proven and cost-effective design that has consequently established itself as the global standard. We are also conducting pilot projects in which we are trialling alternative designs, such as solid panel pylons, and studying the impact of these designs on operations, the environment and operating efficiency. Last but not least, we are also interested in seeing how well the different designs go down with the population.

THE CIRCUITS AND CROSS-ARMS

A typical pylon has one or more transverse members – what we call the “cross-arms”. Attached to these are insulators, to which conductor cables are in turn secured. It’s through these cables that the electricity flows. As a rule, they are reinforced conductors comprised of a steel core and an aluminium sheath, which have different cross-sections depending on their transmission capacity. 380 kV lines typically use a “quad bundle” made up of four conductors for each phase. Each power circuit has three phases. As a rule, a pylon carries several circuits.

Today, the insulators are manufactured from polymer, but most are made of porcelain, or also toughened glass or ceramic. They separate the high voltages in the overhead conductors from the earthed pylons and prevent the current from being conducted from the conductors to the pylons. An earth or “guard” wire is run between the tops of the pylons to protect the live conductors against lightning strikes.

Different types of pylon along the cable route

Depending on the function, we basically distinguish between four categories or types of pylon or transmission tower:

- If a pylon is located in the middle of a straight route, we use what are known as straight-line or suspension towers.

- If the line is curved, tension or anchor towers are positioned at the points where the direction changes. Unlike on suspension towers, where the insulators hang vertically from the tower and carry the conductors, the mechanical tension causes the insulators (called “strain insulators”) on anchor towers to align themselves in the direction of the conductor.

- Where power lines intersect, we use branch pylons.

- Termination pylons or terminal towers are erected where a line is fed into a substation.

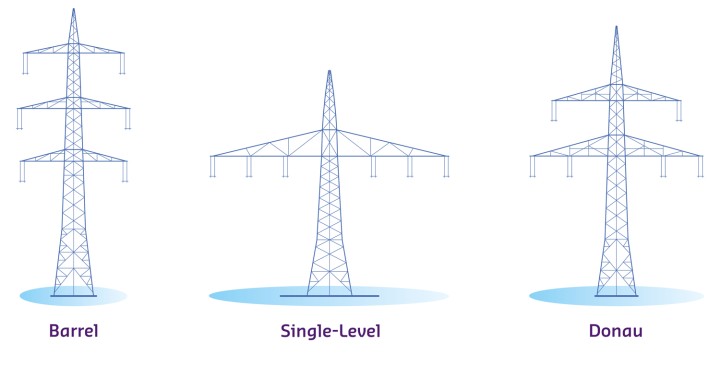

Three designs: barrel, single-level and “Donau” towers

We use different designs of pylon or tower for our overhead lines depending on the local circumstances:

barrel towers, single-level towers and “Donaumasten” or Donau towers. These types of tower differ with respect to their height and the number and length of the cross-arms.

- Barrel towers are three-level towers with the middle level cross-arms being longer than the upper and lower cross-arms, giving the conductor arrangement a barrel-like shape. These towers usually carry two circuits. Their three phases are arranged one below the other. They can make do with narrower routes and are preferably deployed where the width of the route is restricted, such as when cutting through woods or forests.

- Single-level towers have just the one long cross-arm (with one beam on either side) and the three phases are positioned next to one another at the same level. These masts are particularly low-profile (short), but they require wide routes: they are mostly used in the vicinity of airports and airfields.

- Donau towers are two-level towers that have one conductor bundle on either side on the upper level cross-arm and two bundles on each side on the lower level cross-arm; that is, one circuit on either side. This makes them shorter than barrel towers, but narrower than single-level towers.

- Also in use are hybrid towers that have additional cross-arms for carrying 110 kV circuits, for example.

- Amprion will also be trialling solid panel pylons close to the border with the Netherlands as part of the Wesel–Netherlands Project. If you want to find out what distinguishes this type of pylon from the others, please read our brochure.